|

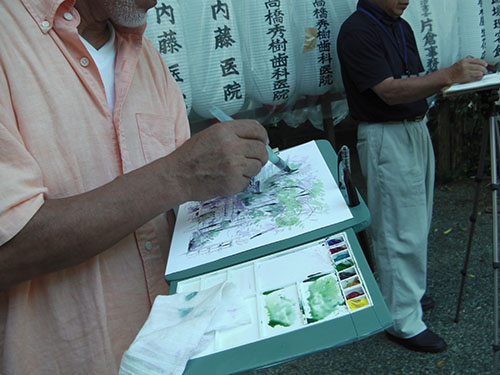

2012 Have sketchbooks and paint pallets on both hands, I wanted to combine these into one. That is the chance of development. 2012. The next day after the General Assembly of the Japan Tourism Sketch Association, development began when we all went sketching. |

|

|

I tried increasing the reality with image software based on the rough above. In those days I called sketch pad, Sk-pad. |

| Based on the drawings, styrol and plastic panels were cut and pasted to make a solid model. If I do not use it in a model, I do not understand the feel I put in my hand. I also inserted paint on the pallet. From this time on, we began to include organic lines on the pallet surface. |

|

|

I actually tried using it. I was confident that this would be usable. However, the right paint palette part was heavy and the balance was bad. |

|

It was still difficult in the model to make organic lines on the pallet. In reality, I placed the paint on the top. |

|

2013 This is a process of sticking the drawing on the placard and carefully cutting it |

|

Cutting a 5 mm plastic board with a cutter is anyhow tough work. |

|

But, the pleasures of making things can not be done at once ... When you are doing each and every one, it is about gradually finishing shape. |

|

Parts are finished. |

|

Slide rails are perfect too!

|

|

Also, ready-made solid paint entered perfectly. |

|

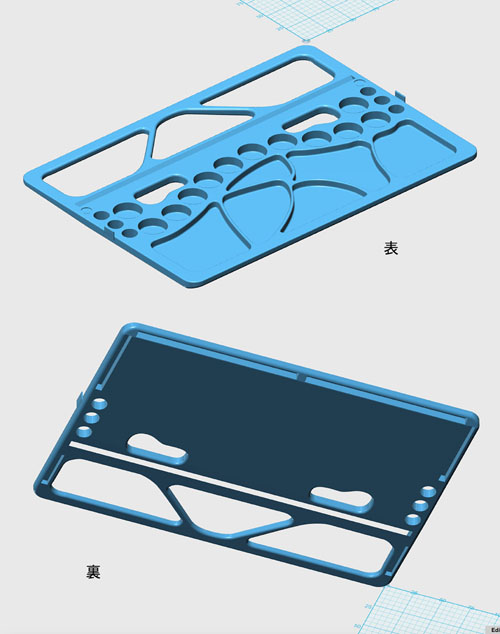

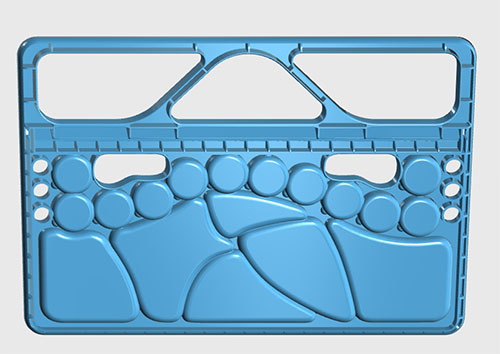

In these two units, I changed the pit of the paint with the difference between the square shape and the round shape and the shape of the paint melting plate. Those cooperated by Yashima Pro Shade Co., Ltd. of Kobe and made by a 3D printer. To make it possible to use either the left or right, the hold part of the finger was made in two places in the handle part. |

|

|

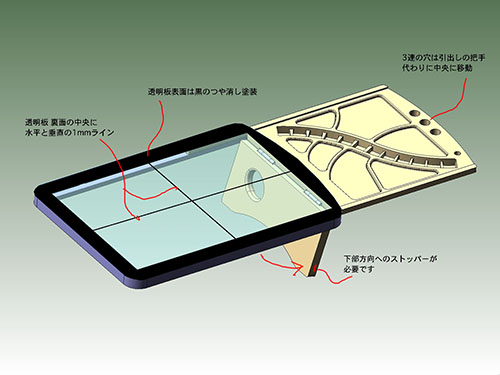

| Rendering screen of 3D-CAD. I was deeply impressed that this will be a product with 3D printers as it is. |

|

2014 Change of thinking |

|

|

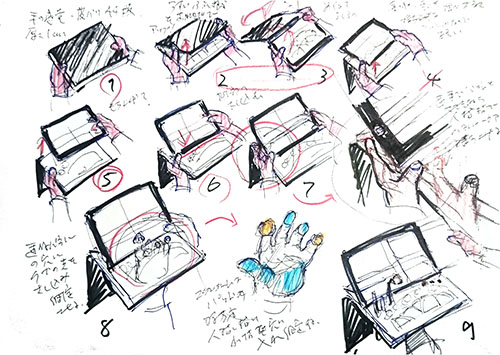

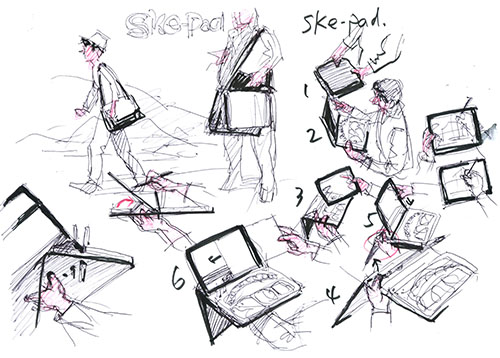

2014 I am considering a style that brings a palette in front from a form that slides to the right with this. The transparent panel part also began to use one light thing. |

|

|

|

2015 I saw it as a moving picture by dividing the palette and the transparent panel and fitting it in the main body. This is a presentation for myself. |

| This was made by molding a mold with oil clay and silicone rubber in a wood mold and hand making the resin. Although it does not go to mass production, it is No. 9 model made about 3 units. It was impossible to hold the fingers in hold. I also thought about the case of including this. |

|

|

2016 |

An image of 3D-CAD of the final idea No. 10 model. |

|

|

|

|

|